Covid-19 spurs increased adoption of Industrial IoT

The Covid-19 pandemic has forced businesses to adapt to a world more reliant on social distancing. In addition to sparking a work from home revolution, new research from satellite provider Inmarsat suggests that the pandemic has inspired businesses to invest more heavily in Industrial IoT architecture.

In the recent report Industrial IoT in the Time of Covid-19, researchers found that decision makers in industries ranging from agriculture to transport and logistics were accelerating their IoT deployments in direct response to the global pandemic. The survey polled 450 IoT decision makers from industrial organizations with more than 250 employees across the globe.

A whopping 84% of respondents said that they were stepping up their investments in IoT architecture in direct response to issues created by the ongoing pandemic. Among this group, 47% have already accelerated their IoT development, while 24% sought to do so over the next 12 months, and 14% planned to continue adoption beyond that.

How can IIoT help?

The impact of the ongoing pandemic in industrial operations has been considerable. The basic tenets of supply and demand have been shifted, even as workforce operations were ground to a halt by shutdowns. Yet, Industrial IoT has emerged as a way to restructure and reinvigorate workforces by increasing automation to both improve efficiency and facilitate social distancing.

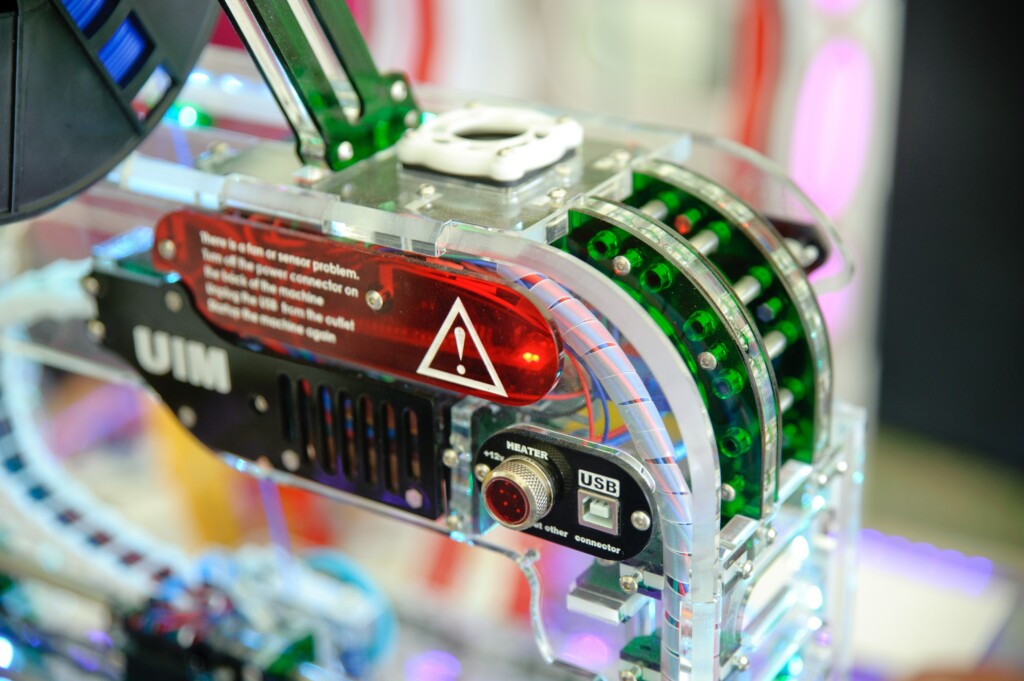

IoT devices such as manufacturing-execution sensors permit floor managers to monitor production remotely, allowing them to perform mission-critical tasks without needing to be onsite. Elsewhere, services like LineVision provide diagnostic sensors that allow companies to monitor and maintain equipment while observing social distancing guidelines.

Companies can even invest in wearable IoT devices for their employees to help track both productivity and their location. Take AGC, for example, which offers watches and safety glasses that collect and transmit data to a central hub, allowing plant managers to monitor employee performance and environmental factors – information that can be used to plot shift changes to control population density in the workplace and better enforce social distancing.

Investing in the Future

These are only some of the ways IIoT is currently helping to face the challenges created by the pandemic. The study found respondents using IoT technologies to address everything from cost efficiency to sustainability to decision making. Trends suggest it’s only the tip of the iceberg, too, as more than half of the respondents claim that Covid-19 has underlined the importance of IoT to their organization.

Each of the sectors represented in the report signaled increased spending on IoT Architecture in the coming months, with the largest investments coming from the petroleum and electric utility markets. The average cost of IoT projects from both sectors is anticipated to run around $3.2 million USD, with some respondents indicating budgets that could climb north of $5 million USD.

“The rapid increase in IoT deployments over the last few years highlights the considerable progress global industry has made to overcome some of the world’s most challenging forces. Those businesses implementing IoT technologies ahead of their competition and across their value chains are those who stand to win in the long term.”

Mike Carter, President of Inmarsat Enterprise

The importance of IoT connectivity

Of course, no IoT deployment will get very far without a reliable internet connection – a fact bore out in the survey’s results. Three out of four respondents reported facing issues with their IoT project directly related to connectivity.

For many companies, the solution to this issue is to invest in multiple connectivity technologies at once, with the average respondent using 3 different connectivity options across their organization.

Each connectivity type brings with it it’s own strengths and challenges. LPWAN (used by 25% of respondents), for example, offers lower costs for device hardware and communications, but doesn’t allow batch data download/upload or firmware updates. WiFi (50%), on the other hand, is useful for transferring large amounts of data at a low cost, but drastically limits the area in which devices can communicate. Cellular (27%) covers a wide area, but can run into coverage issues in remote areas.

A blended solution

Mixing these technologies is no simple task either. Companies hoping to blend multiple connectivity options into their deployments will need to build a system that manages devices over multiple platforms. That system would then need to interact with the APIs of multiple service providers – and the complexities don’t stop there. Say one service provider offers specialized services that the others don’t. Companies would then need to build the equivalent features internally in order to ensure that they are available to the entire deployment.

Enter Soracom. Soracom Air supports cellular and Sigfox connectivity, meaning these options can be blended as needed. This combination allows Soracom to function as a one stop shop for integrating enterprise backend systems.

When it is necessary to blend multiple internet connectivity options, solutions like Soracom Arc enable customers to use virtually any internet connectivity while maintaining the same integration point as cellular and Sigfox. The service allows users to connect directly to the Soracom IoT platform over connection technologies like satellite, WiFi, cellular and more.