How the IoT Helps The Oil and Gas Industry Become More Sustainable

Despite efforts to clean up their operations in recent years, the oil and gas industry is still responsible for more than 40% of the greenhouse gas emissions currently affecting our global climate. This is partly why solar, wind, and other renewable energy sources have become bigger competition for the fossil fuel industry in recent years, particularly as these energy alternatives become more affordable and efficient.

It’s no surprise, then, that governments around the world are pushing the industry to become more environmentally conscious. The EU, for example, has set a target of reducing methane emissions by 55% by 2030 from levels measured in the 1990s.

While the road toward a more sustainable oil and gas industry is long and winding, IoT devices may be helping organizations get there a little sooner.

A Roadmap Toward Sustainable Oil and Gas Operations

In the early 1970s, the United Nations Environment Programme asked the oil and gas industry to form a group dedicated to advancing sustainability within its ranks. Ipieca, the resulting association, was founded in 1974 and continues to coordinate between the sector and the UN. Together, these organizations created 17 sustainable development goals for the industry.

In 2021, Ipieca published a roadmap that looks at ways the oil and gas sector can lower emissions by 2030 while still ensuring global prosperity and health. It includes measurable goals around operations, policy, and resource management that are designed to help the industry work more sustainably – and provide ideal opportunities to implement IoT solutions that benefit the industry and the planet.

The industry currently leverages IoT technologies primarily to track assets and protect against cyber attacks, but it can also use the same technology to protect the environment and create more sustainable operations. IoT projects can help the oil and gas industry in two ways:

- By creating more efficient operations across the entire industry stream – from production to delivery of fuel.

- By helping protect against environmental damage by preventing spills and leaks that might otherwise harm animals and birds, and pollute waterways.

Though the Ipieca roadmap names several players who must be at the table for effective implementation – including local communities, intergovernmental agencies, and nongovernmental organizations – oil and gas companies are key to its success.

Case Studies in Sustainability

Here are some of the specific ways IoT devices are helping create a more sustainable oil and gas industry:

- IoT smart sensors in the field can provide crucial data about pipes, vehicles, and filters. This information can be used to determine when any preemptive maintenance is needed. This helps ensure continued uptime for mission-critical equipment, ensuring that each point along the continuum from production to delivery is operating effectively and efficiently. Estimates say predictive maintenance programs could save oil and gas companies 40% over a reactive approach.

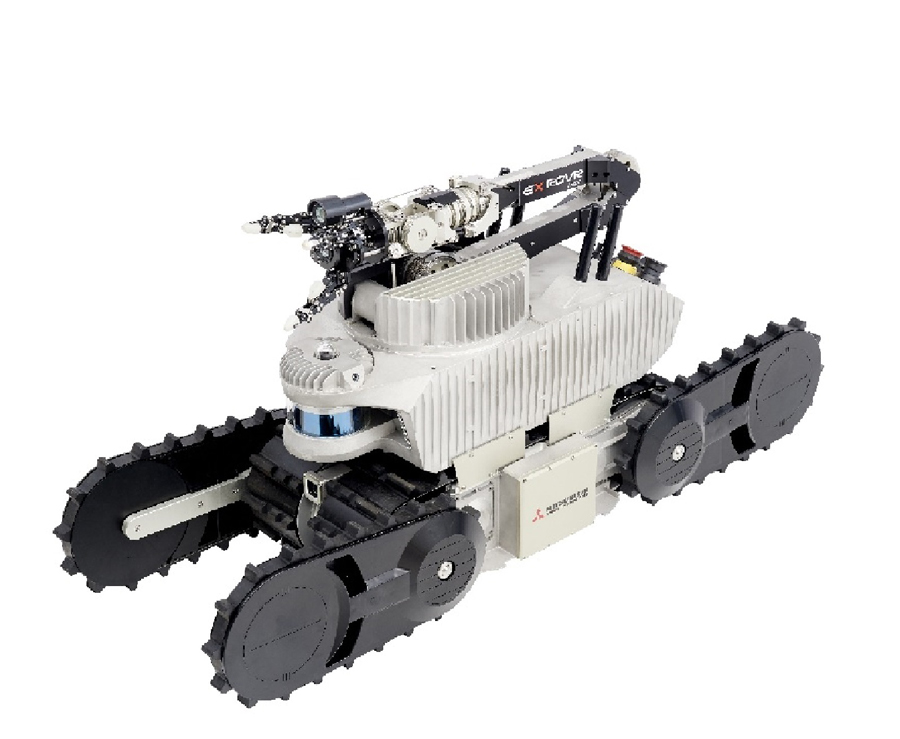

- Robots and drones can be used for inspections, particularly in dangerous locations that are difficult for humans to access. This can help with monitoring the thousands of oil and gas pipelines that distribute fuel across more than 160 countries. See these kinds of robots at work here.

- Digital twins of refineries can help companies evaluate failures and learn how to avoid them in the future. Petrobras, the Brazilian state-run oil company, is rolling out smart twins for all of their refineries in 2022 after a successful AI pilot conducted in a digital twin facility. “We want to increasingly move from a proactive approach to a predictive one,” said Nicolas Simone, Petrobras’ digital transformation and innovation director, in an article about the project.

- Remotely managing petroleum stocks can help oil companies respond more quickly to supply and demand. Predicting variability in demand can be accomplished through data provided by remote sensors that monitor stored fuel inventory. This can help companies determine how much to boost or ramp back production based on the marketplace.

- IoT sensors can monitor real-time weather conditions and activate heating and cooling systems based on that data. This creates more efficient use of resources in direct operations, which, in turn, boosts sustainability.

The IoT market in the energy sector is forecast to grow from US$37.7 billion in 2020 to US$59 billion by 2025. The use of connected devices and sensors to monitor and protect equipment, track assets, and predict maintenance needs is all part of the toolkit the oil and gas industry is building in its quest to reduce emissions and protect the environment in which it operates.

………………

Got a question for Soracom? Whether you’re an existing customer, interested in learning more about our product and services, or want to learn about our Partner program – we’d love to hear from you!