IoT 3D printer

Remote monitoring and operation for industrial 3D fabrication tools

ABOUT

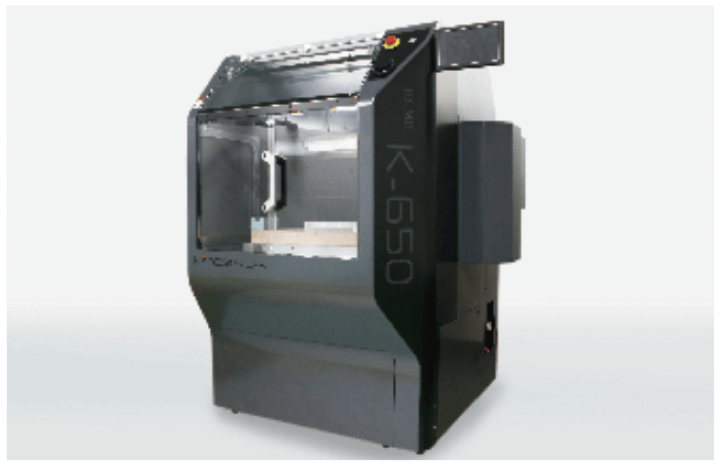

Serious protoyping tools for the 3D modeling age

K’s Design Lab provides a range of 3D design, prototyping, and fabrication tools. In a typical 3D fabrication workflow, once material has passed through the 3D printer it then proceeds to a cutting machine. These advanced precision machining tools allow for cutting free curves and creating fine textures, helping users to create finished models more true to the underlying data.

The 3D-Mill K-650 was designed by K’s Design Lab from a technician-first point of view, giving 3D designers the tools to manipulate a wide range of materials and make use of technology like vacuum forming, part prototyping, and external product design.

CHALLENGE

Remote management and control during the lengthy cutting process

While job length will vary based on size and complexity, a complete cutting operation can take anywhere from a few hours to a day or more.

During cutting, designers can continuously adjust and refine output settings using a tablet connected to the machine. However, it’s often impossible (or extremely inconvenient) for one person to constantly monitoring the entire cutting process. To take advantage of the machine’s full capability, users needed a way to remotely monitor, adjust, and control the cutting workflow.

SOLUTION

WHY SORACOM

A secure wireless channel for remote equipment control

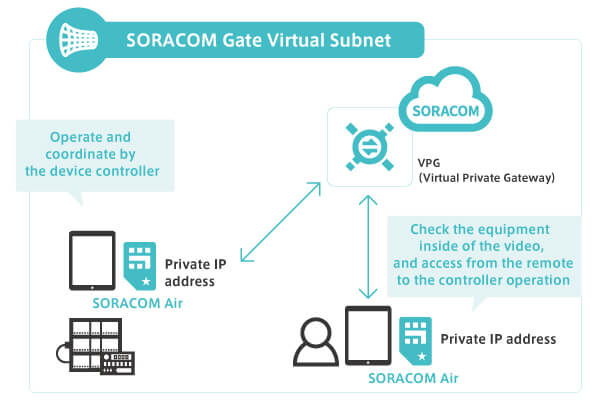

The 3D-Mill K-650 allows users to carry the cutting machine’s controller with them to monitor and operate the cutting machine using a secure mobile data connection provided by the SORACOM Air SIM. K’s Design Lab also created an app that allows the user to customize their own controls for designing, testing, and cutting three-dimensional models.

As Yuji Hara, Representative Director of K’s Design Lab, explains, security was critical: “It was important for us to, for example, be able to loan tablets freely to users while still accessing them securely ourselves. This way we can monitor internal states and adjust or control things as needed.”

To achieve this, K’s Design Lab uses the SORACOM Gate bidirectional IoT LAN service and a Soracom VPG (Virtual Private Gateway). Devices with SORACOM Air SIMs that connect to this VPG reside on the same subnet and make use of private IP addresses, allowing secure communication between tablets, cutting machines, and K’s Design Lab servers.

FUTURE PLANS

Achieving ever-greater manufacturing precision

The increased need for 3D prototyping in product development and crafting today has brought new attention to the entire production process. K’s Design Lab continues to develop new cutting machines that allow makers to enjoy the experience of turning 3D data into real objects and help advanced industrial users to accelerate their prototyping process with precision and efficiency.